the journeymand hammer

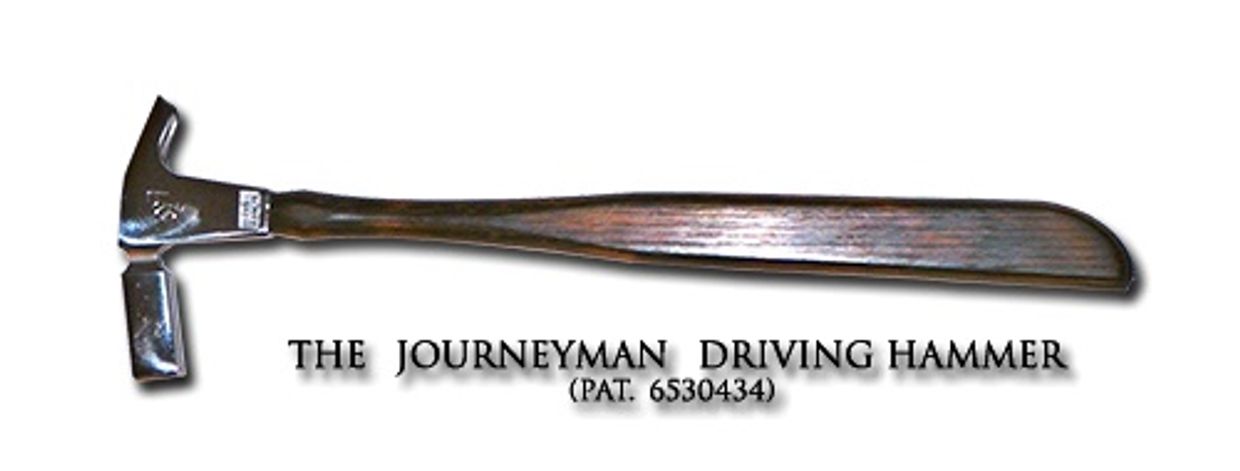

The Journeyman Driving Hammer

Design:

Toolmaker and farrier, Roger Grant, developed and patented this superior design after several years of using various horseshoeing hammers that were out on the commercial market but never finding one that suited him. Finally, he called upon his past experience as a tool and die maker, acquired some tool steel, and went to work at his milling machine to build his own unique design. After a lot of research and development, he finally created one that he liked and the "Journeyman" was born.

Still seeking perfection, he took it around with him and let other horseshoers try it, asking for their input on possible improvements. They told him that the only thing he needed to do was build one for them!

The finished product is a hammer that is not only appealing to the eye, but the "Journeyman" functions as well as it looks.

The Head:

The Journeyman's beautifully balanced head is made of the highest grade tool steel and is heavily hand polished. The slot of the claws is hand-ground to a critical dimension which also provides for a sharp cutting edge.This allows each nail that is wrung off to be sheared off clean.This design actually cuts the nail starting at two opposite corners rather than merely twisting the nail in two.

The square bottom of the claws eliminates the problem of the nail end hanging up and instead lets it fall free. (However, Trying to wring a nail off above the bevel one may have some difficulty. Should the nail need to be driven at that height, a longer shank nail should be used in order to achieve the correct width of a properly made clinch.)

The Handle:

No discussion of superior design would be complete without speaking of the handle.The ergonomic design of the handle will enable the farrier to work more easily and with less fatigue. Each handle is hand shaped and sanded.The sides are flattened which allows the hammer to square it's self up in the farrier's hand thus enabling the nail to be driven with better accuracy.

The heel of the "Journeyman" handle is rounded which in turn takes the snap out of the wrist as the nail is driven and relieves shock the farrier's wrist has to absorb as with a conventional handle. After the handle is shaped it is then flame scorched to open up the pores of the wood. It is then immersed in boiled linseed oil in order to restore the wood's natural characteristics and extend the handle's life. It is finally finished by being steel wooled by hand and then again hand rubbed to a smooth fine furniture finish. The replacement handles are also finished to the same exacting standards as those that are installed in a new hammer.

The exceptional balance, along with it's Patented design and other fine features, make the "Journeyman" a nail driving instrument. The head and handle are each hand finished down to the finest detail. The Patented claw design makes it the only hammer available that actually shears the nail in half rather than twisting it in two. The claws have a hand ground straight slot that ends with a square bottom. The nail is cleanly cut and falls free. No more having to dig the nail end out of the claws to keep on working because the cutting area is larger and not in one spot. This design makes the "Journeyman" a lot different than the other hammers.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.